WIND POWER

The wind blows in Kansas.

If you grew up in Western Kansas, you probably know that better than most. There is substantial data to confirm that statement, and state leaders are making the most of it. Over the last several years, you may have seen massive wind turbines transported on trucks or installed all over the state. Wind energy is a clean fuel source. It doesn’t pollute the air like power sources that rely on the combustion of fossil fuels like coal or gas.

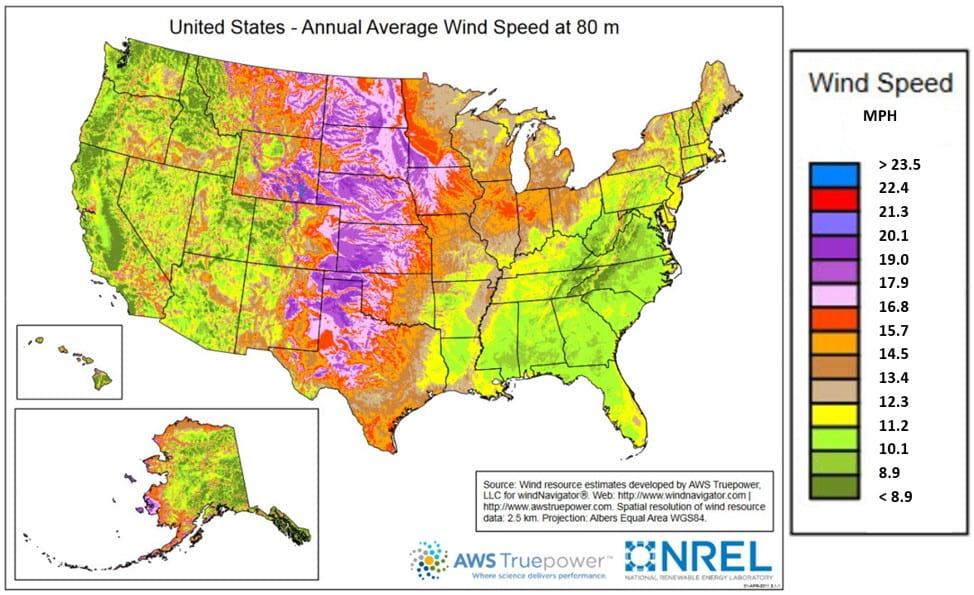

According to the National Renewable Energy Laboratory, Kansas has the second highest potential capacity for wind power behind Texas. Sitting squarely in the center of America’s wind tunnel (see purple area on map), Kansas has led the nation over the past decade in all measured categories of scaling up renewable electricity generation.

So why doesn’t K-State take advantage of this abundant commodity? The short answer is that the cost of instituting the change combined with other competing institutional needs would make that a challenge. K-State could feasibly install utility scale wind turbines to generate approximately half of the Campus’ power needs, but electricity is needed even on calm days when the wind isn’t blowing. In addition, the estimated cost for installation would be in the range of $25 million along with maintenance and operation expenses that would average around $75 thousand per year.

wind isn’t blowing. In addition, the estimated cost for installation would be in the range of $25 million along with maintenance and operation expenses that would average around $75 thousand per year.

While installing our own turbines isn’t feasible at this time, another option would provide access to competitively priced renewable energy through a new program offered by Westar Energy. Under this program, known as the Renewables Direct Program, K-State’s main campus will receive approximately 50 percent of its current electrical load at a fixed price for 20 years. The energy will be provided by a new 300-megawatt wind farm being built in northern Kansas and is scheduled to be on line in 2020. K-State is one of 14 Kansas organizations that will receive electricity from the wind farm. The anticipated savings for utilizing this program will be approximately $180,000 to $200,000 annually.

K-State has worked aggressively to lower its energy usage over the past several years and the work has paid off. KSU has seen a net decrease of both energy usage and expense during simultaneous growth in building space. The Renewables Direct program is just one example of how that has been accomplished.

Welcome to Our Team!

Ronald Banks was hired as a Custodial Specialist.

He is working for Steve Greinke.

Patrick O’Neill was hired as a Landscape Tech I.

He is working for Mark Fronce.

Jessica Ott was hired as a Project Manager.

She is working for Diana Hutchison.

Lawrence Davis was hired as a Custodial Specialist.

He is working for Quentin Rawlins.

Janan Walker was hired as a Custodial Specialist.

She is working for Mary Grubbs.

Rosanna Carvalho was hired as an Arch Eng Project Manager.

She is working for Diana Hutchison.

Raymond Fahrny was hired as a Maintenance & Repair Tech.

He is working for Mike Paph.

Shannon Ruder was hired as a Supply Specialist.

She is working for Carla Bishop.

Beverly Saunders was hired as a Custodial Specialist.

She is working for Mary Grubbs.

Aaron Burger was hired as a Custodial Specialist.

He is working for Quentin Rawlins.

Christine Blau was hired as a Custodial Specialist.

She is working for Steve Greinke.

Angel Brown was hired as a Custodial Specialist.

She is working for Steve Greinke.

Adam Miller was hired as a Custodial Specialist.

He is working for Beverly Price.

Faith Bliss was hired as a Custodial Specialist.

She is working for Thomas O’Briant.

Linda Craghead was hired as Director of Custodial Services.

She is working for Casey Lauer.

Terry Sprecker was hired as Landscape Tech I.

He is working for Mark Fronce.

Durga Prasad Sarilla was hired as a Systems Analyst.

He is working for Gary Weishaar.

On The Move!

Many Thanks!

KUDOS!

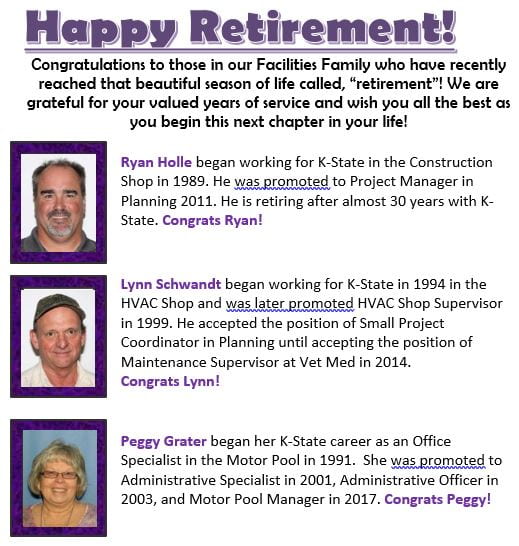

Happy Retirement!

Happy Birthday!

‘Be The Change You Want To See’

By Thomas O’Briant, Custodial Manager, Vet Med Facilities

When asked to write an article about myself and the Vet Med Custodial crew, the task seemed daunting. However, after considering the chance to promote our efforts, I am excited to share about the many projects we have started as well as our future endeavors.

My name is Thomas O’Briant and Manhattan is my hometown. Prior to working for K-State, I spent more than twenty years as a Creative Art Director for Ballards Sporting Goods and another 8 years as Head Custodian for USD 458 in Basehor, KS. My wife and I wanted to move back to Manhattan after being away for 15 years. In December of 2017, I joined K-State’s Vet Med as an Evening Custodial Supervisor. I was promoted to Custodial Manager in spring of 2018.

Ballards Sporting Goods and another 8 years as Head Custodian for USD 458 in Basehor, KS. My wife and I wanted to move back to Manhattan after being away for 15 years. In December of 2017, I joined K-State’s Vet Med as an Evening Custodial Supervisor. I was promoted to Custodial Manager in spring of 2018.

There are differences between working for a USD school district and a university: while here at K-State, I have had to adjust to a more structured environment that is always evolving but, fortunately, I have a strong support staff that has helps to keep me on course.

Within Vet Med Facilities, we have made several changes over the last year. In addition to hiring some new employees, we have instituted training classes so that all Vet Med custodians sanitize and clean using the same benchmark standards. Our modified Team Cleaning concept has been very successful, and we have increased work productivity during the past few months. Last summer, Vet Med administrators requested that we change our work schedule for the evening crew. While the adjustment brought some challenges, it allowed our employees to have more time with their families. We also recently changed our chemical supplier. This should help us control our chemical usage and costs.

We are initiating new procedures including the use of expectation sheets (work zone sign offs), and restroom check sheets. We have created a “Shout Out” board for our employees who receive accolades from Vet Med clients and staff. Teamwork is another area we have worked on by encouraging employees to  support each other and offer assistance if needed. Several of our employees volunteer to help and support each other, creating a better-balanced and more enjoyable workplace.

support each other and offer assistance if needed. Several of our employees volunteer to help and support each other, creating a better-balanced and more enjoyable workplace.

During a discussion about interacting with clients and staff members, I shared my philosophy that ‘we get back what we put into the world’. I challenge myself and my staff to extend ourselves, and be the change that we want to see in the world. Smile when meeting new people. Say ‘hi’ when passing a stranger. Open doors for everyone. Be patient when listening to others. Say “Sir’ and “Ma’am’ often and try to be as helpful as possible.

I have met many nice people within Facilities, and have observed the countless times facilities employees have solved situations that seemed unsolvable. The amount of work orders submitted daily seems virtually unmanageable, but with hard work and determination, the facilities work always seems to be completed.

I am very fortunate to have supportive administrators such as Director Allen Leikam and Facilities Associate Vice President Ryan Swanson. It is with their guidance (as well as the support from the Vet Med Administration), that we are able to create a positive Custodial Team, a clean hospital environment, and support all the efforts of our K-State Facilities Organization. I believe we are getting a little better every day. I feel lucky to have this position and the crew I get to work with on a daily basis. I look forward to the future and the growth within our Facilities organization.

Welcome To Our TEAM!

John Hannan was hired as a HVAC Technician for Zone 2.

He is working for Mike Paph

Mina Gotti was hired as a Custodial Specialist.

She is working for Stephanie Brecheisen.

Rachel Stevenson was hired as a Mail Specialist.

She is working for Bridgett Henry.

Kallie Kolterman was hired as a Mail Specialist.

She is working for Bridgett Henry.

Amy Mahan was hired as a Custodial Specialist.

She is working for Quentin Rawlins.

Jessica Shepherd was hired as a Custodial Specialist.

She is working for Roger Schneider.

Josiah Hall was hired as a Custodial Specialist.

He is working for Mike Price.

Cornelius Bly was hired as a Maintenance & Repair Technician.

He is working for Shelly Hauck.

Quincy Wallace was hired as a Custodial Specialist.

He is working for Steve Greinke.

Darrin Dohrman was hired as a Landscape Tech II.

He is working for Joe Myers.

Doug Mann was hired as a Landscape Tech II.

He is working for Joe Myers.

Galen Asbury was hired as a Maintenance & Repair Technician.

He is working for Shelly Hauck.