MANHATTAN, Kan. – A team of Kansas State University watershed specialists have revised a publication with tips on how to safeguard the state’s water resources while providing grazing animals with the water they need. Continue reading “K-State Releases Guidelines for On-Farm Alternative Water Sources”

Top 10 Things to Keep in Mind with Free Choice Minerals

Jason Warner, extension cow-calf specialist

Minerals and vitamins are a very challenging aspect of beef cattle nutrition. This is mostly because plant mineral and vitamin precursor levels are influenced by many factors including soils, water, and forage growing conditions. As such, mineral plans can and do vary significantly from one operation to the next. Regardless of the specifics of your program, the following are my top 10 most important things to keep in mind with free choice minerals. Continue reading “Top 10 Things to Keep in Mind with Free Choice Minerals”

How Does Estrus Synchronization Work?

Sandy Johnson, extension beef specialist, Colby

As we go through each breeding season, questions arise about changes, intentional or otherwise, regarding various synchronization protocols. What if I gave X rather than Y, or did something on day W rather than day Z; will it matter? In order to understand how estrus synchronization works and the importance of what happens in each step, a basic understanding of the tools used and how they influence the components of the estrous cycle is needed. Continue reading “How Does Estrus Synchronization Work?”

Highly Pathogenic Avian Influenza Detections in Livestock

AJ Tarpoff, DVM, Extension Veterinarian

News reports and updates have been published over the past several weeks about the emergence of highly pathogenic avian influenza (HPAI) impacting dairy herds in several states. Investigations are ongoing and information continues to surface about this evolving situation. To stay up to date on the current scenario, USDA has created a landing page that can be found here: https://www.aphis.usda.gov/livestock-poultry-disease/avian/avian-influenza/hpai-detections/livestock Continue reading “Highly Pathogenic Avian Influenza Detections in Livestock”

Managing Drought Risk with Annual Forage Insurance

Jenny Ifft, Agricultural Policy Extension Specialist

Nearly all of Kansas is currently experiencing abnormally dry or moderate drought conditions. For producers who grow annual crops for the purpose of feeding cattle or other livestock, Annual Forage Insurance (AFI) is a tool to manage drought risk. Continue reading “Managing Drought Risk with Annual Forage Insurance”

Managing Production Systems for the Future

Jason Warner, extension cow-calf specialist

The term “sustainability” has been used a lot in recent years in nearly every industry. It seems that it has become more common for companies and organizations to have a claim that a product or service has been produced “sustainably”, and this usually is in reference to the environment. Keeping in mind the environmental impact on how goods are produced and working to better understand and subsequently minimize our footprint on the environment is certainly a good thing for society. Continue reading “Managing Production Systems for the Future”

How Does Western Ragweed Impact Pasture Production?

by Keith Harmoney, range scientist, Hays

Western ragweed (Ambrosia psilostachya) is one of the most common native forbs found throughout Kansas rangelands. Western ragweed is a perennial plant that can form dense colonies from growth of lateral creeping rootstalks. It’s used by wildlife for cover and for food, and the high protein content of western ragweed seed makes it a valuable staple of bobwhite quail and other grassland bird diets. Cattle also graze on western ragweed and utilized up to 50% of the western ragweed produced in moderately stocked pastures when measured in a long-term grazing trial at the Ag. Research Center in Hays. Continue reading “How Does Western Ragweed Impact Pasture Production?”

Management Considerations for June 2024

COW HERD MANAGEMENT

- For spring-calving cow herds:

- Monitor BCS relative to feed/forage availability.

- Formulate your plan if you anticipate early-weaning or supplementing on grass.

- Schedule early pregnancy checking activities with your vet if not already done.

- For late-summer and early-fall calving cow herds:

- Ensure mature cows are ≥ 5.0 and 2-4 year old females are ≥ 6.0 at calving.

- Review your calving health protocols as needed.

- For free-choice salt and mineral programs:

- Record date and amount of product offered, calculate herd or pasture consumption.

- Adjust how you are offering product to cattle if they over- or under-consume.

- If consumption is 2X the target intake, then cost will be too!

- Properly store bags and pallets to avoid damage and product loss.

- For bulls at the start of the breeding season:

- Watch for injury so you can intervene and treat bulls promptly if needed.

- Ensure they are aggressively covering cows.

- Monitor BCS, particularly on young bulls.

- If pulling bulls from cows to manage the length of the breeding season, schedule those dates and have them on the calendar in advance.

CALF MANAGEMENT

- If considering creep feeding calves, make sure you understand what your objective is by doing so and calculate the value of gain relative to cost of gain.

- Monitor calves for summer respiratory illness.

- Schedule any pre-weaning vaccination or processing activities.

GENERAL MANAGEMENT

- Visit KSUBeef.org for info and events!

- Evaluate early-summer grass growth and adjust your grazing plan as needed.

- Make concerted efforts to control invasive species in pastures.

- Take inventory of remaining forages and feedstuffs carried over to this fall.

- Use the Management Minder tool on KSUBeef.org to plan key management activities for your cow herd for the rest of the year https://cowweb.exnet.iastate.edu/CowWeb/faces/Index.jsp.

- Employ multiple strategies and chemistries for controlling flies and insects.

With high feeder calf prices, consider price risk management tools. - Make and evaluate important production calculations (always a good time for this):

-

- Calving distribution (% 1st cycle, % 2nd cycle, % 3rd cycle)

- Calving interval

- % calf crop (# calves weaned/# cows exposed for breeding).

Mineral Supplement Selection Tips

One of the challenges cattle producers face is determining which mineral supplement they will use during the upcoming grazing season. Often this decision is based on the information provided on the mineral tag and price sheet. Although, price is an important consideration, other factors such as the concentrations of the minerals in the mix relative to the animals’ requirements and sources of minerals used should be considered.

The first step in selecting a mineral supplement is to know what you are shopping for. Mineral mixes are often categorized based on the concentration of phosphorous in the mineral mix. Phosphorous is often deficient in cattle consuming forage-based diets and is our first priority in developing mineral supplements for grazing cattle. The amount of phosphorous required in a mineral mix to meet the requirements of a cowherd is a function of forage phosphorous content (determined via forage mineral analysis) and animal requirements, which are driven by mature body weight and production stage. A mineral mix that contains 6 to 10% Phosphorous would be adequate in many situations.

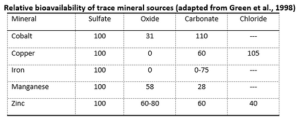

The next step is to spend some time reading the mineral tag. The guaranteed analysis section of the tag guarantees the concentration of the minerals listed. In general, the more guarantees the better, and if a mineral is not listed then it is not guaranteed to be in the mineral. The sources of the minerals used in the mix also warrant consideration as mineral sources differ in bio- availability (Table 1). For example copper sulfate is 100% available to the animal, whereas copper oxide is unavailable.

For more information about mineral supplementation, see “Questions and Answers on Beef Cattle Nutrition (http://www.oznet.ksu.edu/library/lvstk2/c733.pdf).

For more information, contact Justin Waggoner at jwaggon@ksu.edu

It’s Not Always About the Money

If you have an employee who seems to continually be bothering you about not being paid enough, there are usually two possibilities. 1) You’re a tightwad and you’re not paying them enough; or 2) the person is disgruntled about their role in the organization. To find out if the answer is #1, make a few phone calls to managers you trust in your general geography and find out what your neighbors are paying for similar jobs in your industry. If you’re within 50¢ or so per hour, then move on to answer #2. Some people are just better employees than others. If this person is worth more than the ‘scale’, you’d better pay more to keep them.

But “pay” can come in many forms. You can “buy” an employee’s loyalty and general job satisfaction with many perks other than another few cents or bucks per hour. Make sure your insurance, savings investment, and/or profit sharing plans are at least in line with the industry. This is especially important if this person has a family to look after. Non-monetary benefits include things like flexible time off. Those early mornings and long days are a lot easier to take if a person knows they can take Thursday afternoons off for a child’s ballgame or whatever.

What about goals? Have you asked your employee what they want out of this position? They may want to move up in the organization or have opportunities for a management role elsewhere. You can be selfish about this or you can take on the role of mentor and teacher. By taking care of your employee and training them for a leadership role they will most certainly be a better employee, and will have a harder time leaving for a different job. And even if they do leave for a different opportunity, they will give such a glowing report on your leadership and team approach, you can be certain to find a good, young person to replace them.

The question you need to ask yourself is “Do you really want this person around for the long haul?” If you DO, take some time to privately evaluate your plans, then take some more time one-on-one with this employee to find out their long-term needs and goals. If you DON’T want this person to remain in the organization, you still need to get your plans in order because after you inform this person they are not what your organization needs, you’d better have a pretty good plan set up to attract a quality person to replace them.

For more information, contact Justin Waggoner at jwaggon@ksu.edu