“Supplementing Cows During Cold Weather”

By: Justin Waggoner, Ph.D., Beef Systems Specialist

The New Year often brings with it some of the coldest months of the year. Most cattle producers know and appreciate that cold weather increases nutrient requirements. However, the real question is what should producers feed or supplement when the wind blows and the mercury barely registers on the thermometer.

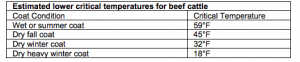

Cattle are most comfortable within the thermoneutral zone when temperatures are neither too warm nor cold. During the winter months, cattle experience cold stress anytime the effective ambient temperature, which takes into account wind chill, humidity, etc., drops below the lower critical temperature. The lower critical temperature is influenced by both environmental and animal factors including hair coat and tissue insulation (body condition). The table below lists the estimated lower critical temperatures of cattle in good body condition with different hair coats. In wet conditions, cattle can begin experiencing cold stress at 59°F, which would be a relatively mild winter day. However, if cattle have time to develop a sufficient winter coat, the estimated lower critical temperature under dry conditions is 18°F.

Cold stress increases maintenance energy requirements but does not impact protein, mineral or vitamin requirements. The general rule of thumb (for a cow in good body condition, BCS = 5 or greater) is to increase the energy density of the ration by 1% for each degree (Fahrenheit) below the lower critical temperature. The classic response to cold stress in confinement situations is an increase in voluntary intake. However, it has been documented that grazing beef cows may spend less time grazing as temperatures decline below freezing, which reduces forage intake, and makes the challenge of meeting the cow’s nutrient requirements even greater. In many cases, feeding a greater amount of low-quality hay will replace grazed forages but may not provide sufficient energy. Therefore, providing additional energy by feeding a relatively higher-quality hay or fiber-based supplement (DDGS, Corn gluten feed, or Soybean Hulls) may be required. If fiber-based energy sources are not available, small amounts (2-3 lbs) starch-based concentrates may also be used as energy supplements.

For more information, contact Justin Waggoner at jwaggon@ksu.edu.